Benefits of Opting for A Laser Cutting Service

March 8, 2020

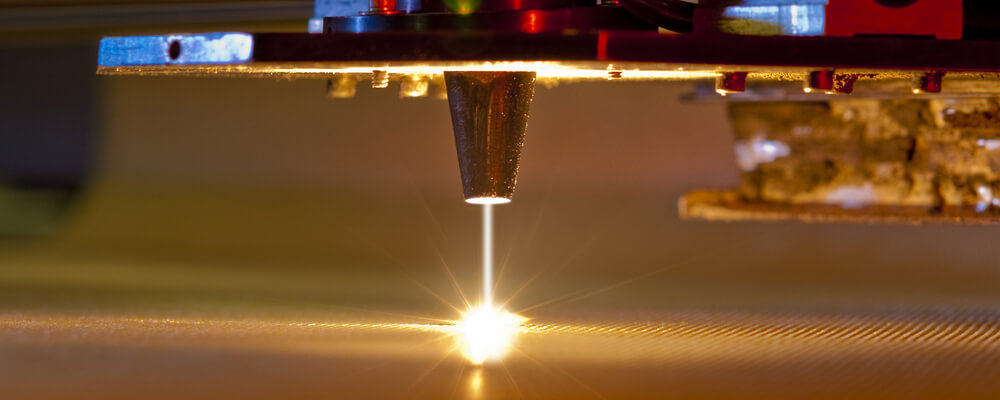

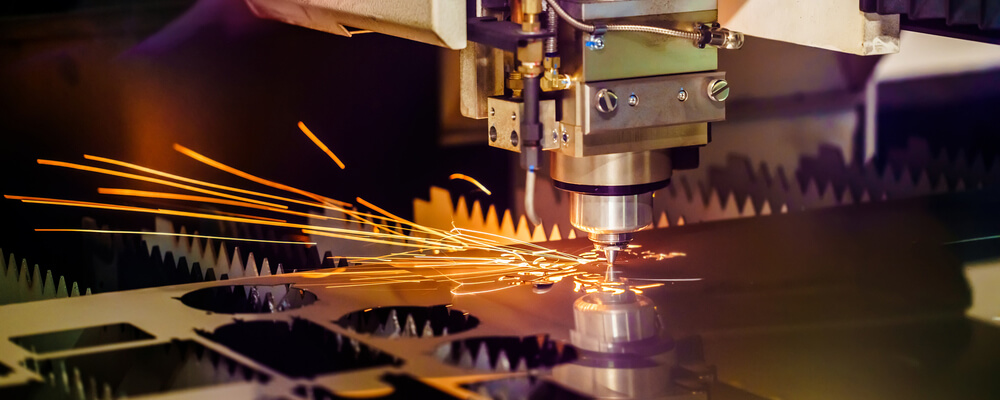

For a layman, laser cutting means slicing metals using lasers. Which is a correct definition if you want to know what the process means. But apart from this simple definition, laser cutting can prove highly beneficial in upgrading the manufacturing process. It is a precise way of shaping and cutting metals like steel and aluminum as well as conserving energy when compared to the plasma cutting process. When you incorporate laser cutting machines, you achieve high precision designing and quality cuts. It allows you to perform high-speed complex cuts and shapes without changing too many tools. With laser cutting technology you can reduce the contamination of your final product or item. Here we discuss the five advantages associated with laser cutting Dubai service.

Clean Edges

When you incorporate laser cutting, you achieve a high level of precision and quality cuts as compared to the traditional cutting mechanism. This technology also reduced the wearing of the metal and can be used for creating the most complex and small cuts. The heating of the metals allows the machines to perform narrow and cleaner cuts.

No Warping

The high processing speeds of a laser cutting machine allows only a small area to get heated, which reduces the distortion or warping of the material. The results are more precise and you get a high-quality end product.

Less Costs

As it is an automatic process, laser cutting reduces the amount of time and money spent on pressing, shearing, etc. This also reduces the need for changing tools, tool maintenance, or need to hire specialized personnel. As it is a precise and no hard-tooling mechanism, you can cut detailed shapes faster than other cutting methods.

Less Scraps

As it is one of the most precise cutting processes, you can easily cut any metal in one go, which means you will reduce the wastage of material. There are various laser cutting techniques like nesting, tabbing, and much more that can help in saving scrap.

Customization

One of the best things about this method is that you customize each and every single piece based on your requirements. You can get perfect cuts or holes that are perfectly designed and shaped no matter how big or small. When you incorporate laser cutting in your manufacturing process, designing is no barrier to achieving the beautiful piece of work.

Call us now for more details.